The Importance Of Paying Attention To The Words in Electrical Standards

The words used in any standard are of vital importance. In pretty much all cases they have been debated upon for hours in meetings by representatives of various organisations or in the case of international standards, by international subject matter experts. This is particularly true for the UK national wiring (installation) standard, BS 7671.

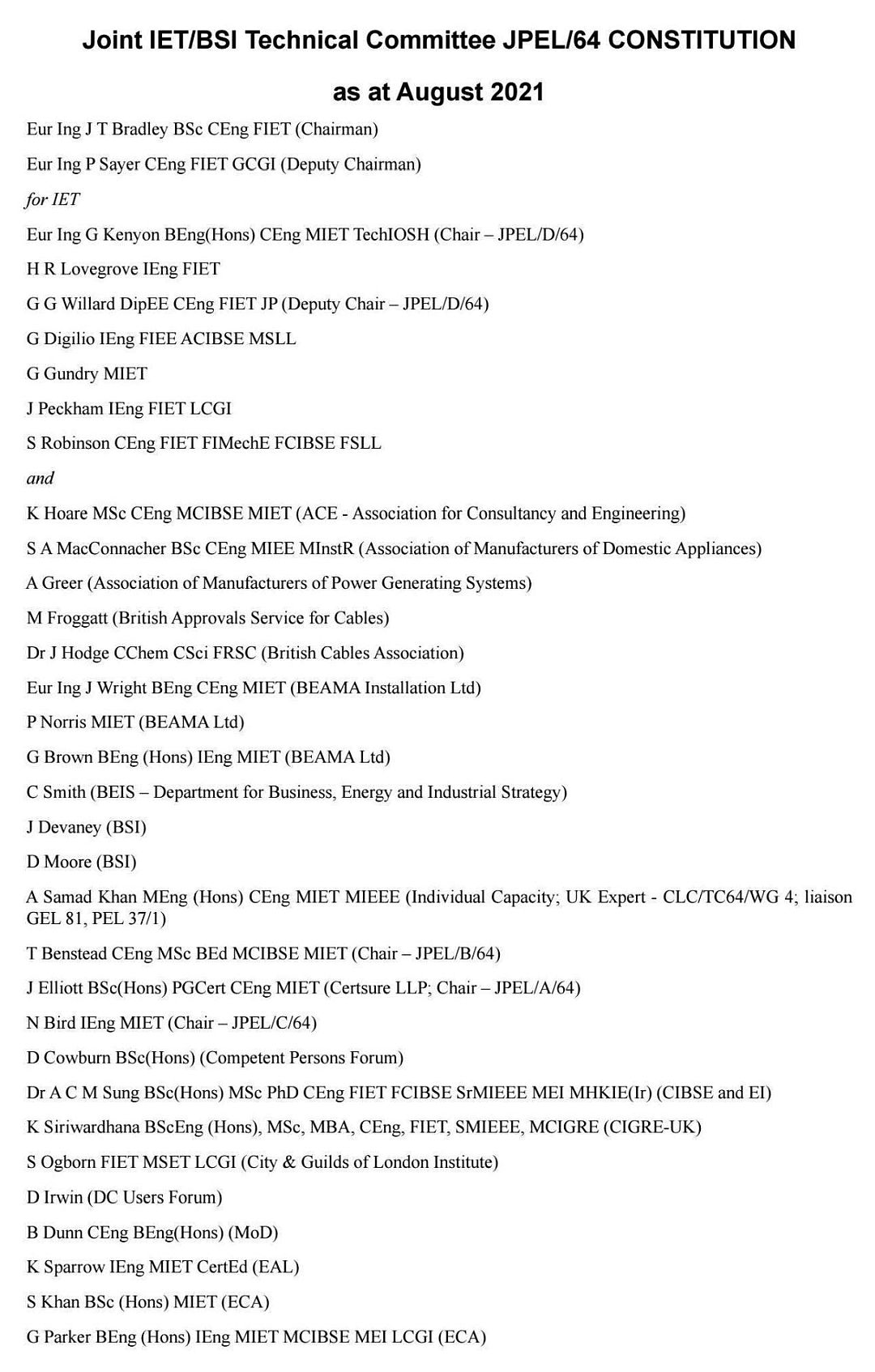

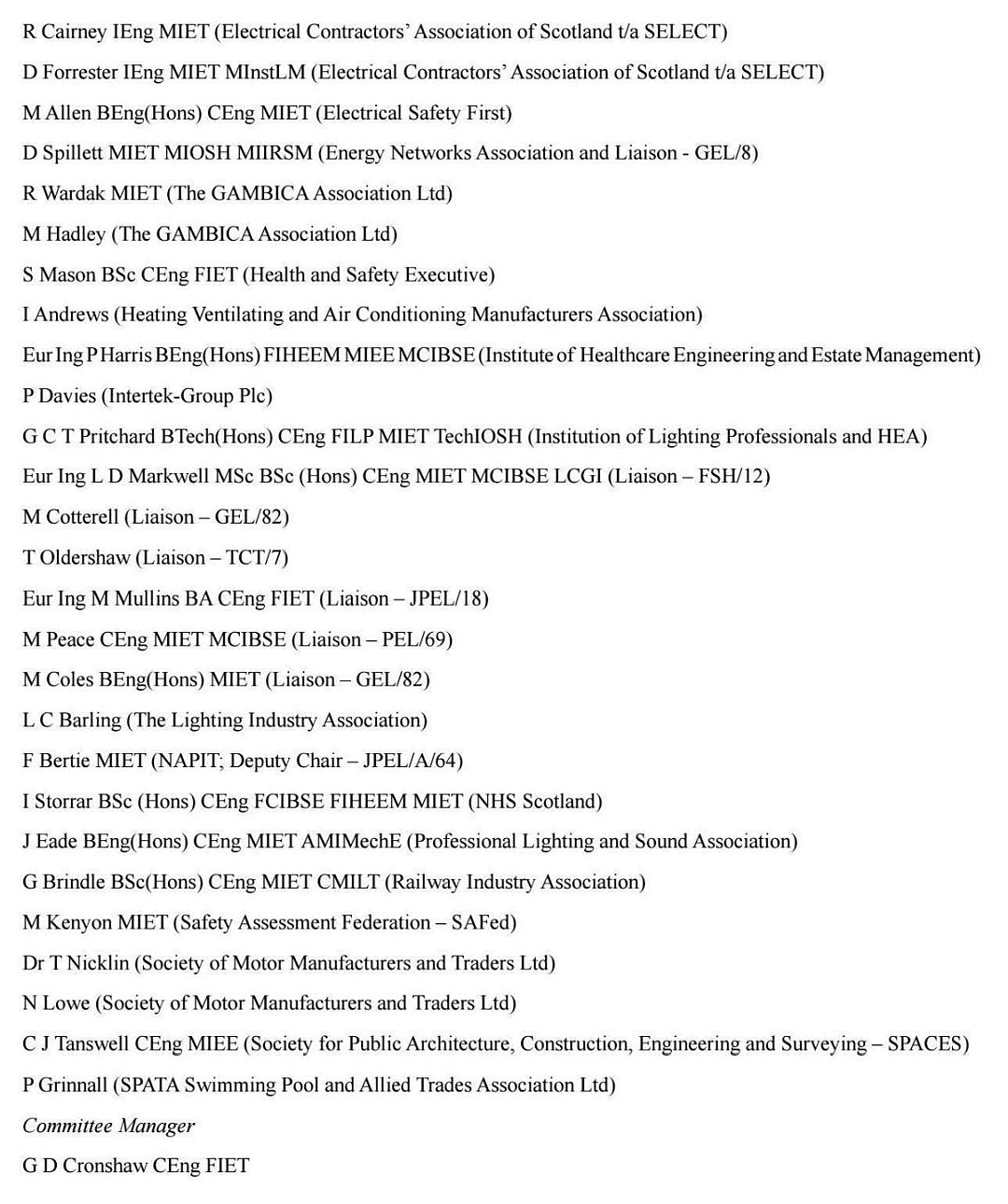

The maintenance of BS 7671 remains under the responsibility of the Institute of Engineering and Technology (IET) and the British Standards Institute (BSI). This is achieved via a standards committee known as the Joint Power and Electrical Committee 64 (JPEL/64) which has representatives from all strata of industry, academia, governing bodies and interested parties.

It can therefore be concluded that nothing in the Standard is included by accident, in particular the selection of words and phrases for the particular clauses.

Which words are the most important?

It is true to say that all the words in the Standard are important, however there is a hierarchy in the importance.

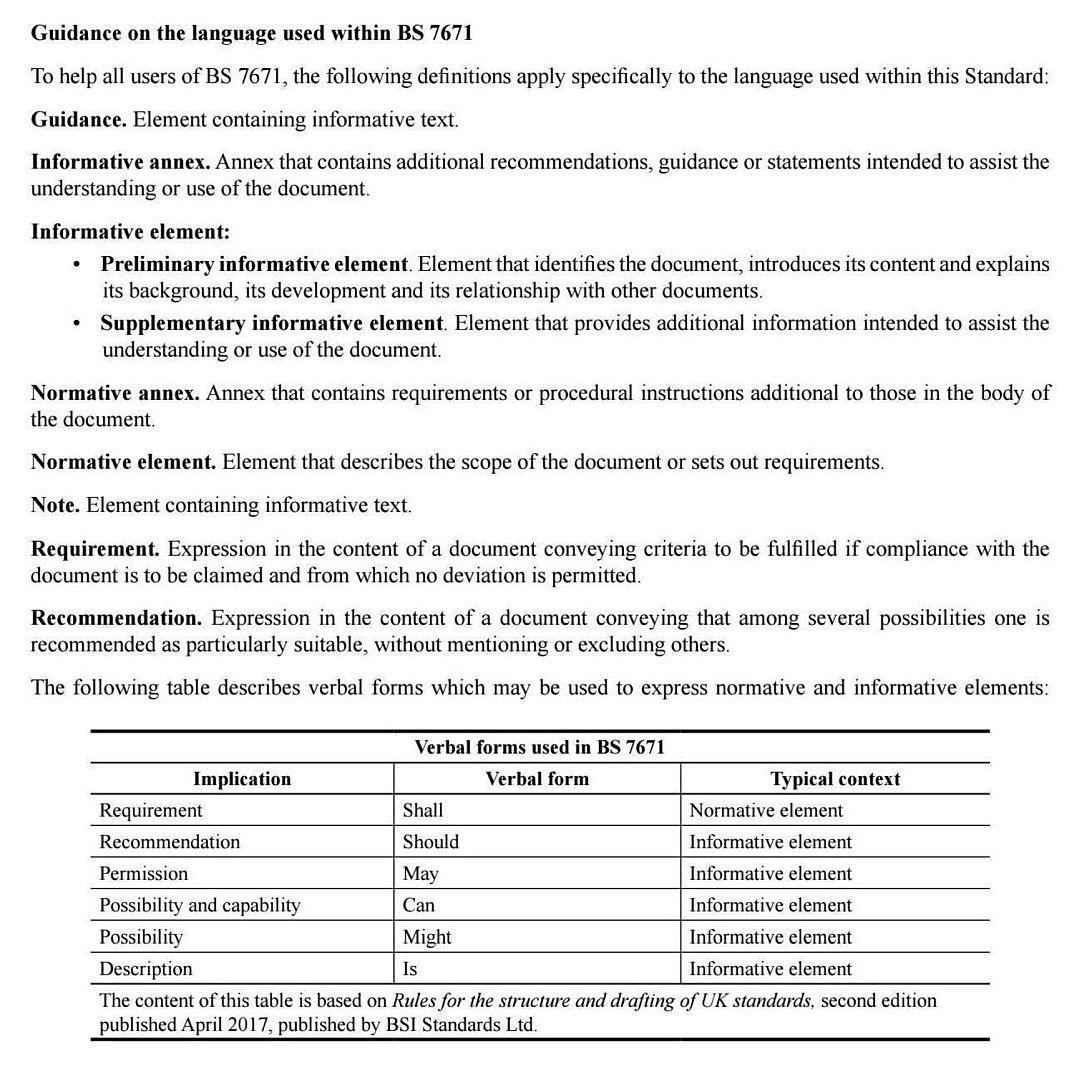

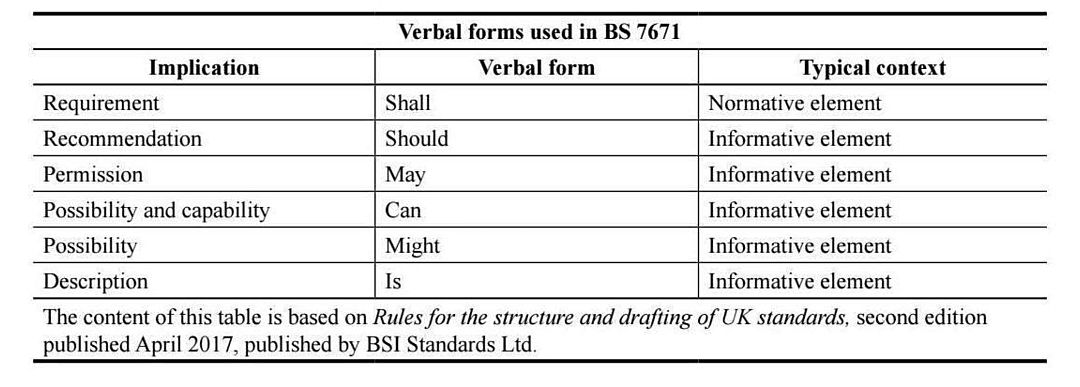

Page 18 of BS7671:2018+Amd2(2022) (shown below) provides some guidance that will be used to explain the hierarchy.

The first thing to point out is that all British Standards are typically non-statutory specifications, guides or codes of practice. This means that there is no obligation to follow them, however, in the case of BS 7671 it has been cited in numerous legal cases.

What gives it particular clout is that the Health and Safety Executive (HSE) acknowledge that electrical installations that comply with BS 7671 are likely to also comply with statutory legislation, such as the Electricity at Work Regulations 1989, thus drawing a parallel between the two documents.

The verbal forms used in BS 7671 was provided by BSI and is an extract from the document “Rules for structure and drafting of UK Standards.”

The first distinction readers/users can make from the take is the words “normative” and “informative.” Readers/users of the Standard should therefore be aware that any clause containing “normative elements” are mandatory requirements that must be followed to comply with the Standard. Regulations that are mandatory, thus typically contain the word “shall.”

All other terms are in essence “information” to provide context or suggest to readers that additional actions are deemed beneficial. These are represented in regulations by the use of terms such as “should,” “may,” “can,” “might,” or “is.” The implication being recommendations, permissions, possibilities, capabilities, or descriptions.

The most controversial of these terms is “recommendations” thus needs a deeper review.

BS7671 defines a recommendation as an “Expression in the content of a document conveying that among several possibilities one is recommended as particularly suitable, without mentioning or excluding others.”

The key question however is that if recommendations are informative elements (thus may not need to be followed for compliance with BS 7671), does this mean that they can simply be ignored?

Let’s look at some examples to illustrate the impact of doing nothing….

An example of the impact for ignoring recommendations

Regulation 421.1.7 mandates the use of arc fault detection devices (AFDDs) on all final circuits supplying socket-outlets up to 32 A where those circuits are installed within four mentioned locations. However, the regulation also recommends the use of AFDDs on the same circuit within all other locations too.

For example, in a residential premises AFDDs are recommended only. So using AFDDs on all final circuits supplying socket-outlets up to 32 A is a particularly suitable idea. Ignoring this portion of the regulation does not simply negate the obligation to the client.

The reader/user of the Standard must therefore demonstrate how they are going to meet the recommendation by another means if they choose not to install AFDDs. If they ignore the statement they simply have no defence in a court of law, thus doing nothing, is not an option.

This is a good example to highlight the importance of recommendations as it is beyond doubt that AFDDs would be a welcome inclusion within residential premises. The cable insulation type and the use of combustible electrical accessories are such that readily carbonise thus sustaining an arc fault. The installation may have been modified by unqualified persons and/or where the levels of electrical maintenance are not appropriate as per current guidance. Thus warranting the use of arc fault detection device technology to enhance the safety of the installation by abating or stemming the risk of fire.

The text within regulation 421.1.7 was agreed upon by all representatives as shown on pages 13 and 14 of BS 7671, thus another way of looking at this point is that by not implementing the recommendation, the reader/user of the Standard is effectively deciding to ignore the advice and guidance of all the subject matter technical experts as listed below:

These contain representatives from organisations such as the HSE, IET, CIBSE, SELECT, ECA, Certsure, NAPIT, BEAMA and many more. All of whom have debated over copious hours on the contents of the Standard and reached positions where consensus has prevailed.

The argument against this stance….

I know what you are thinking, this type of position is very convenient for manufacturers of the various safety devices and is just a way to sell more products.

It is true in part that manufacturers have a desire to service the needs of industry, however this doesn’t necessarily have to be viewed in a negative manner. In that, electrical manufacturers must be central in the drive to achieve increasingly safer electrical installations. This is true from either an electric shock or fire-risk related perspective.

Additionally, the investments that are manufacturers make in research and development for renewable technology, in an attempt to reach the UK government targets of net zero by 2050 means that manufacturers must offer such solutions to market in order to permit installers to offer these solutions to their clients.

Remember, according to the legislation, it is the duty holder of the installation that needs to make an appropriate decision on the safety of their electrical installations. It is thus the role of the installer to provide guidance on the various solutions available and for manufacturers to continue to develop increasingly intelligent product lines that can accomplish the desire for a safer, more efficient, and less wasteful electrical future.

In summary

The requirements of the Standard do not magically disappear if they are ignored, in fact the “defence” element alluded to in Regulation 29 of the Electricity at Work Regulations 1989 becomes more tenuous if compliance cannot be substantiated. There is a parallel drawn between compliance with the Standard (BS 7671) and compliance with the statutory legislation.

Crucially, it is apparent that although recommendations are informative elements, the readers/users of the Standard are obligated to do something and simply cannot do nothing!

A risk assessment, alternative means, or simply following the recommendation within BS 7671 are all examples of doing something, i.e. the clause has been considered and acted upon as suitable to the specific project/ installation/ or duty holders decision.

Finally, readers/users of the Standard should be mindful of the requirements and the implications of the words used. They are carefully selected in order to convey a specific meaning/ direction in an attempt to ensure that the design and erection of electrical installations is the safest and most functional as possible, in light of advances in technology and new considerations.

How do I get started with online electrical training?

There’s never been a better time to invest in developing your electrical skills. Today, online electrical training is the fastest, most convenient and cost-effective way, to gain in-demand electrical skills. XS Training Ltd is established as a leading UK online electrical training provider.

Why wait? It’s the ideal time to get started training for your NVQ today! Call us on 0800 170 0294, or click here to get your questions answered.